Building Information Modeling (BIM) has been developing new trends for quite a long time, as BIM is no longer consigned to only the biggest firms. Specialists have said BIM process gives substantial business benefits, regardless of the level of execution.

Many have referred to BIM’s capacity to give more steady, precise and less time-consuming project documentation.

AEC firms that need to be ‘fit for business’ in 2017 should know about the BIM trends and be prepared for BIM process. 3D designs utilizing BIM are presently settled as the new standard, making it substantially simpler to view plans with particular building system set up.

BIM builds up the cost plans, controls different other areas while working under a BIM process, from the design of structures to framework for daily maintenance.

The accompanying BIM trends will profoundly affect the way AEC teams design, build and even operate structures in the near future. Thus, you should be aware of the latest BIM trends to achieve best out of your projects.

Augmented reality

Augmented reality (AR) has given another approach to utilizing 3D modeling. AEC experts are adopting this trend to help designers in securing their design contracts and real estate’s deal through real-time property visualization.

AR incorporated with BIM has brought changes in the streamlined procedure for architects, designers, engineers, and builders. Architects can actually interact with their virtual models, considerably which is less demanding to control before it’s too late instead of a physical model that must be redesigned if any changes are required.

Augmented reality headsets are as of now being used by project managers for on-site visualization of the infrastructure.

AR is a mobile solution that flawlessly coordinates with Revit and SketchUp, permitting designers to effortlessly launch their 3D models just before them at genuine scale.

Pre-fabrication and Automation

The efficient advantages of offsite construction have been perceived for a long time and have positively utilized. There’s a good possibility this system will get a solid boost in 2017. As currently, it’s possible to assemble a pre-manufactured home in 24 hours!

For e.g., drones have demonstrated can be used in many activities such as for assessing out of reach areas of a building. Hence, we can hope to see the more extensive usage of automation in pre-fabrication to streamline the manufacturing procedure.

Most importantly, 3D modeling empowers organizations to better comprehend and optimize BIM process before they go into creation or development.

3D Printing

Associating 3D printing abilities to the model allows organizations to bring that virtual idea into reality. From fast prototyping and model making to creating custom parts for application, added manufacturing is ensuring sway on construction.

The expansion of 3D printing capacities to ventures is requiring a more prominent level of tech savvy among the venture team, much like the ascent of BIM and CAD accomplished for engineering positions and architectural design.

3D Laser Scanning

The scanner is a capable laser recording of a structure that catches a site’s shape and appearance and transforms them into a cloud of data points that can be transported into a BIM model.

Though scanner can be costly however numerous AEC firms can legitimize the forthright cost with the increases in proficiency on tasks and extra consulting expenses.

Both cost field safety and cost savings are achieved by importing in laser scans into Revit models. Prefabrication and coordination of MEP systems establishment save rework costs after implementing the scanner.

Mobiles and Clouds

As we know, the workforce in the construction business is often scattered across different sites. Therefore, we can hope to see more extensive use of cloud storage for data, accessible through mobiles from the site, to make data more promptly accessible for all the parties.

Autodesk’s BIM 360 Field is one such data management software with cloud abilities. This application joins mobile technology with productive cloud-based collaboration.

It helps groups work together consistently, making field information available to off-site groups. It permits you to track the quality and advancement of the construction work with simple, customization formats. Including work statuses and construction issues.

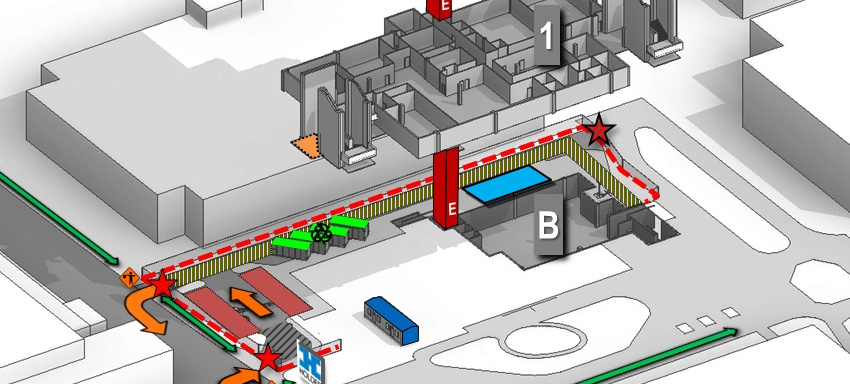

Employee and Equipment Tracking

Wearable gadgets that monitor laborers’ location and capacities, for example, heart rate to machine and hardware telematics intended to help manage and upgrade, the innovation guarantees work process effectiveness, cost savings, and enhanced safety.

Additionally, surveillance cameras, GPS tracking, and controlled access system over Wi-Fi and mesh networks are institutionalizing and better-controlling site and equipment access.