When considering the AEC industry, precision and efficiency are paramount. From towering skyscrapers to sprawling residential complexes, every detail must be meticulously planned and executed and to do so accurate and detailed drawings or modelling is a must for any building contractor. With the comprehensive drawings, they can streamline the construction and ramp up the project at a greater pace.

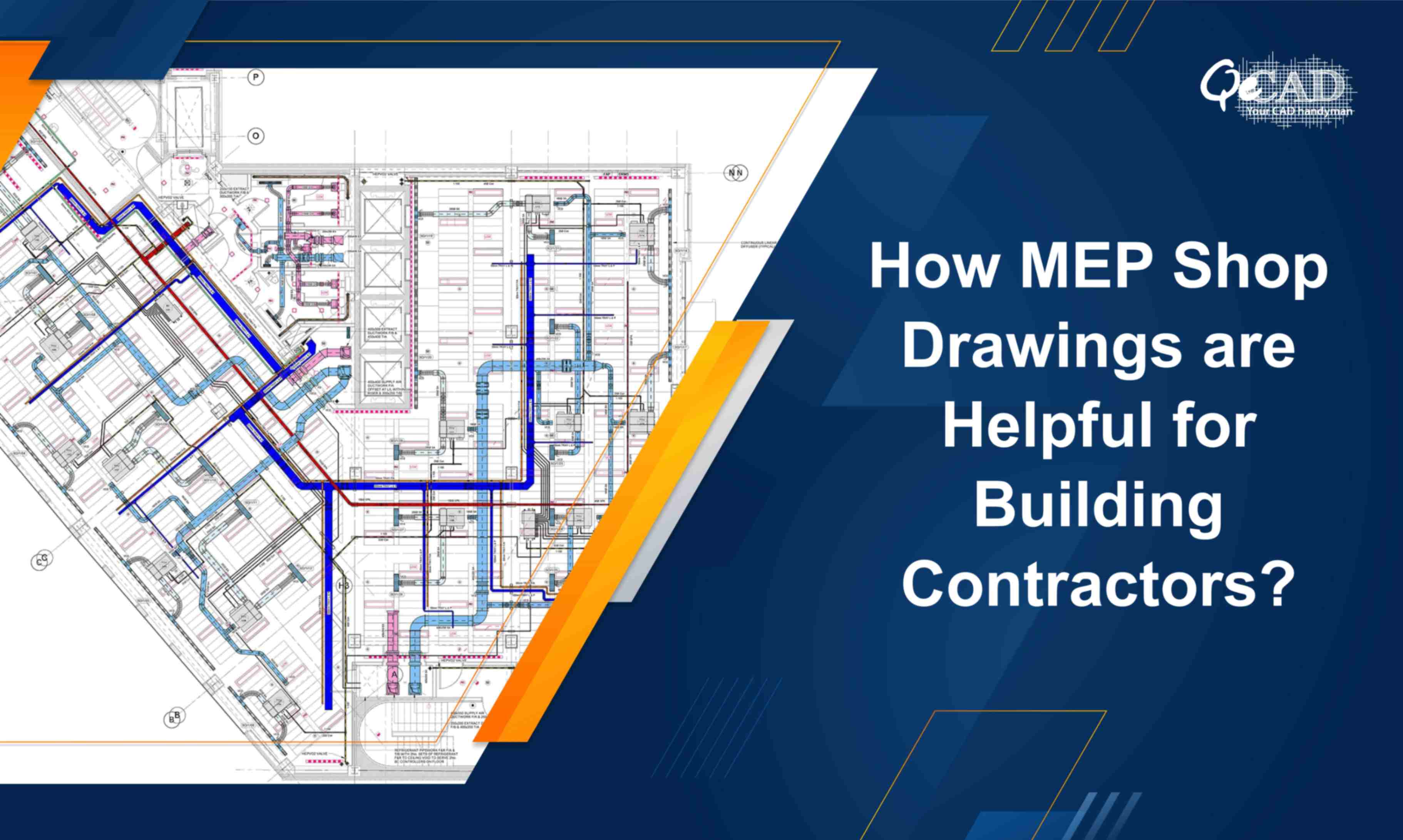

The MEP shop drawings step in as invaluable tools for building contractors. These detailed diagrams provide a comprehensive roadmap for the installation and coordination of MEP systems within a building.

Let’s delve into the manifold benefits that MEP Shop Drawing Services offer to contractors while ensuring smoother project execution and enhanced outcomes. But first, let’s get into the common challenges faced by the MEP contractors.

Key Challenges Faced by Contractors in MEP Projects

- Coordination Issues

As we know MEP systems do involve multiple disciplines that must work in harmony to avoid any clashes or conflicts. Coordination challenges arise when different MEP components intersect or occupy the same physical space. Without proper coordination, conflicts can lead to costly rework, delays, and disruptions to the construction schedule.

- Complexity of System Integration

Integrating various MEP systems with the architectural and structural elements requires careful planning and execution. Each system has its own unique requirements and specifications that must be aligned with the overall project goals and constraints. Contractors must ensure that MEP designs are compatible with the building layouts and structural configurations to achieve optimal performance and efficiency.

- Compliance with Regulations and Standards

Meeting building codes, regulations, and industry standards is paramount in MEP design and installation. Contractors often face the challenge of staying updated with evolving regulations and ensuring that MEP systems adhere to safety, environmental, and efficiency standards. Non-compliance with these may lead to delays in the project, legal complications, and potential safety risks.

- Budget and Cost Management

MEP systems represent a substantial portion of construction expenses. Contractors face the challenge of equalizing the budget constraints with the need to deliver top-notch MEP installations.

- Sustainability and Energy Efficiency

The growing focus on sustainability and energy efficiency introduces additional complexity to MEP projects. Contractors must incorporate eco-friendly practices and energy-efficient MEP solutions while maintaining project feasibility and cost-effectiveness. Achieving sustainability goals requires careful selection of materials, systems, and technologies that reduce environmental footprint thereby enhancing the long-term operational efficiency.

Addressing these MEP challenges requires proactive planning, collaboration among project stakeholders, and accurate MEP BIM Services.

Why MEP Shop Drawings are a Must for Building Contractors?

- Clarity and Coordination

MEP shop drawings serve as a visual guide that outlines the exact placement, routing, and interrelationship of various MEP components. By integrating mechanical, electrical, and plumbing systems into a single cohesive plan, these drawings eliminate the ambiguity and potential clashes between different trades. Contractors can foresee and resolve these spatial conflicts early on, thereby minimizing costly rework and delays during the construction phase.

- Accurate Material Estimation

For contractors, accurate material estimation is crucial for budgeting and procurement. MEP shop drawings provide precise measurements and specifications of each component, enabling contractors to procure materials in the right quantities and specifications. This minimizes the waste and reduces the risk of shortages or excess inventory thereby optimizing overall project costs.

- Effective Communication and Collaboration

Fluent communication and collaboration are the keys to project success. MEP shop drawings facilitate clear communication among AEC professionals. By visually representing complex systems in a detailed manner, these drawings ensure that all parties have a unified understanding of the project requirements and objectives. This alignment fosters teamwork and reduces misunderstandings, promoting a streamlined construction process.

- Improved Project Planning

Successful project planning hinges on minute detailing and foresight. MEP shop drawings provide contractors with a comprehensive overview of the MEP systems, including installation sequences, timelines, and dependencies. With this information handy, contractors can create realistic schedules, allocate resources efficiently, and coordinate construction activities seamlessly. This proactive approach enhances project management capabilities and contributes to on-time project delivery.

- Quality Assurance

In the AEC industry, adhering to design intent and building codes is non-negotiable. MEP shop drawings serve as a benchmark for quality assurance by aligning construction activities with approved designs and specifications. Contractors can conduct thorough reviews and inspections against these drawings to identify deviations or discrepancies early in the construction process. This proactive quality control minimizes errors, enhances construction accuracy, and upholds project integrity.

- Facilitates Off-Site Fabrication

Off-site fabrication is increasingly embraced for its efficiency and quality control benefits. MEP shop drawings provide essential information for prefabrication and modular construction processes. Contractors can leverage these drawings to plan and design MEP components that can be assembled off-site, reducing on-site labor requirements and accelerating construction timelines. This prefabrication approach enhances construction productivity while maintaining stringent quality standards.

- Supports Retrofitting and Renovation Projects

MEP shop drawings are equally invaluable for retrofitting and renovation projects, where existing building conditions must be meticulously analyzed and integrated with new MEP systems. These drawings provide contractors with a clear roadmap for integrating upgrades or modifications into the existing infrastructure, ensuring compatibility and minimizing disruption to ongoing operations.

- Documentation and As-Built Drawings

MEP shop drawings serve as valuable documentation for future reference on project completion. They provide comprehensive documentation of the installed MEP systems, including modifications and adjustments made during construction. As-built drawings derived from MEP shop drawings accurately reflect the final layout and configuration of MEP components, aiding in facility management, maintenance, and future expansions.

Conclusion

MEP shop drawings are crucial in contemporary construction practices, providing numerous advantages to building contractors. From enhancing coordination and communication to optimizing resource allocation and supporting quality assurance, these detailed diagrams serve as indispensable tools for ensuring project efficiency and precision. By leveraging MEP shop drawings, contractors can navigate complex construction challenges with confidence, delivering top-notch projects that meet the industry standards.