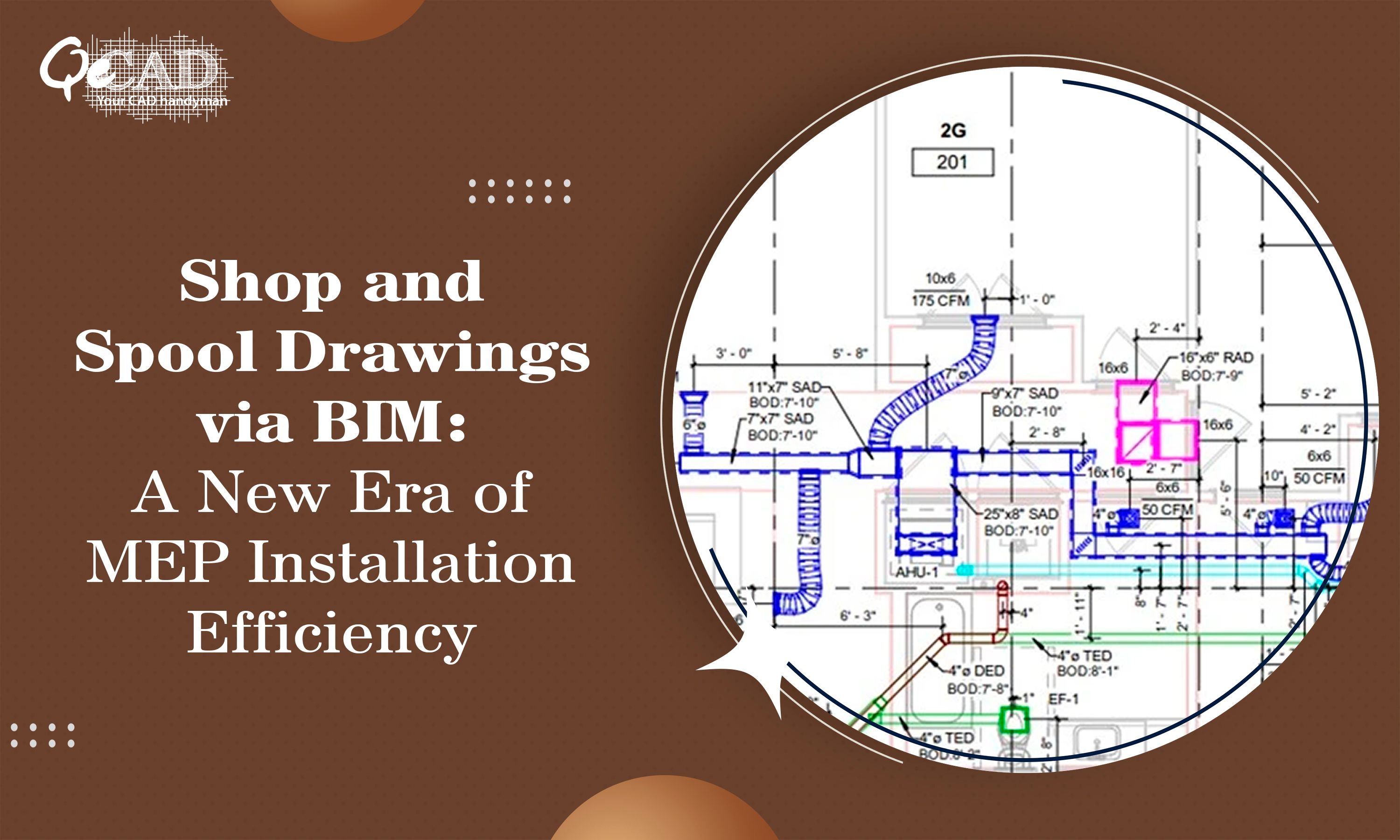

The integration of BIM in MEP (Mechanical, Electrical, and Plumbing) design and construction is revolutionizing the way many contractors approach the complexities of the onsite installations. Among the many BIM-driven innovations, MEP Shop Drawings and Spool Sheets are gaining significant attention for their potential to streamline the installations, reduce the errors and optimize the workflows.

In this blog, we’ll explore how BIM technology is shaping the future of MEP installations on construction sites by using Shop and Spool Sheets.

Understanding MEP Shop Drawings

MEP Shop Drawings are highly illustrative, project-specific technical drawings used to plan and execute the MEP installations. These drawings act as a bridge between the design as well as the construction phases thereby converting the conceptual designs into practical, buildable instructions for the contractors and fabricators.

These drawings are tailored to reflect the real-world conditions including site constraints, material specifications along with the installation methods. Created using BIM tools, these Shop Drawings are crucial for ensuring precision, avoiding clashes as well as facilitating smooth onsite execution.

Types of MEP Drawings

MEP drawings are categorized based on their role in the construction process. Each type fulfils a unique purpose making sure that every aspect of the MEP systems is clearly defined and executed:

- Design Drawings

These are conceptual or schematic drawings created during the initial project phase. Design Drawings outlines the overall MEP layout showing the placement of mechanical, electrical as well as the plumbing systems without getting into the intricate details. They serve as a foundation for developing Shop and Spool Sheets.

- Shop Drawings

Shop Drawings are the detailed versions of the Design Drawings. They include precise measurements, material specifications and fabrication instructions. These are created post-design phase and are tailored for construction as well as prefabrication highlighting any sort of modifications needed to adapt the design to the real-world conditions.

- Spool Drawings

Spool Drawings focuses on the pre-fabricated sections or “spools” of MEP systems such as ductwork, piping or electrical conduits. These drawings provide assembly-level details for components that are fabricated offsite ensuring they fit seamlessly during the installation.

- As-Built Drawings

As-Built Drawings document the actual construction capturing any changes made during the project to reflect what has been installed onsite. These are critical for the facility management as well as future renovations.

- Coordination Drawings

Coordination Drawings are created to detect and address conflicts between the MEP systems and other building components (architectural and structural). MEP Coordination Services ensure that all the systems work together harmoniously within the available space.

- Hanger Drawings

Hanger Drawings detail the layout and placement of the support systems, commonly referred to as hangers for MEP components such as pipes, ducts and the cable trays. These drawings ensure that all the MEP systems are securely anchored and supported thereby minimizing the risk of sagging, vibrations or any misalignment during or after the installation.

- Sleeve Drawings

Sleeve Drawings outline the locations and dimensions of openings or “sleeves” required in walls, floors and ceilings for the passage of MEP components like pipes, conduits and ducts. These drawings are crucial during the early stages of construction to ensure that all penetrations are accounted for and coordinated with the other trades.

The Role of BIM in MEP Shop and Spool Sheets

BIM is the backbone of modern construction and it has drastically changed how MEP systems are designed, fabricated and installed. When it comes to MEP Shop and Spool Sheets, BIM provides a highly detailed and collaborative environment where all system components can be visualized, tested and optimized in a digital model before any physical work begins.

- Accurate and Coordinated Designs

BIM allows MEP designers to generate precise, fully coordinated 3D models of all mechanical, electrical as well as the plumbing systems. These models can be integrated with the architectural and structural designs to ensure that every system is perfectly aligned with the building’s framework.

- Reducing Errors and Rework

Traditionally, the MEP installations were riddled with errors stemming from discrepancies between the design and the actual onsite conditions. With BIM, these issues are caught in the design phase through clash detection.

- Improved Prefabrication and Offsite Manufacturing

BIM-driven Shop and Spool Sheets allows the MEP systems to be prefabricated offsite with precision. Prefabrication speeds up the construction timeline as it allows for components to be built in the controlled environments before being delivered to the job site. With highly accurate MEP Shop Drawing Services, the prefabrication process is faster, reducing delays caused by onsite fabrication. This leads to a more efficient installation, as workers can install pre-assembled components quickly.

- Real-Time Collaboration and Communication

With BIM, the teams can collaborate in real time, accessing a central digital model that ensures that everyone is working from the same source of truth. This is particularly valuable in complex MEP installations where different teams like designers, contractors, fabricators and installers, need to work closely together. The integration of Shop and Spool Sheets within this shared environment improves communication, minimizes misunderstandings, and ensures seamless project progress.

- Cost Savings and Efficiency

One of the major benefits of using BIM for MEP Shop and Spool Sheets is cost efficiency. By reducing errors, reworks and delays, BIM allows for better control over the construction costs.

How BIM Improves Onsite MEP Installation

The advantages of the MEP Shop and Spool Sheets via BIM are directly felt on the job site, where the impact on the speed and quality of MEP installation is significant:

- Faster Onsite Installation: With prefabricated spools and precise Shop Sheets, the installation process is expedited.

- Reduced Risk of Site Accidents: Pre-fabrication minimizes complex onsite tasks like welding or cutting, enhancing safety.

- Better Project Coordination: Shop and Spool Sheets improve alignment between contractors and installers.

- Improved Quality Control: Prefabricated components built to high standards ensure better quality installation.

Conclusion

The shift to using BIM for MEP Shop and Spool Sheets is transforming the way construction teams approach the MEP installation. By improving the accuracy of designs, facilitating collaboration and enabling offsite prefabrication, BIM is helping to reduce costs, minimize errors and improve overall efficiency on construction sites.